Video Demonstration of Controls and Operation of Ball-Balancing Platform:

Video Demonstration of Initial Testing:

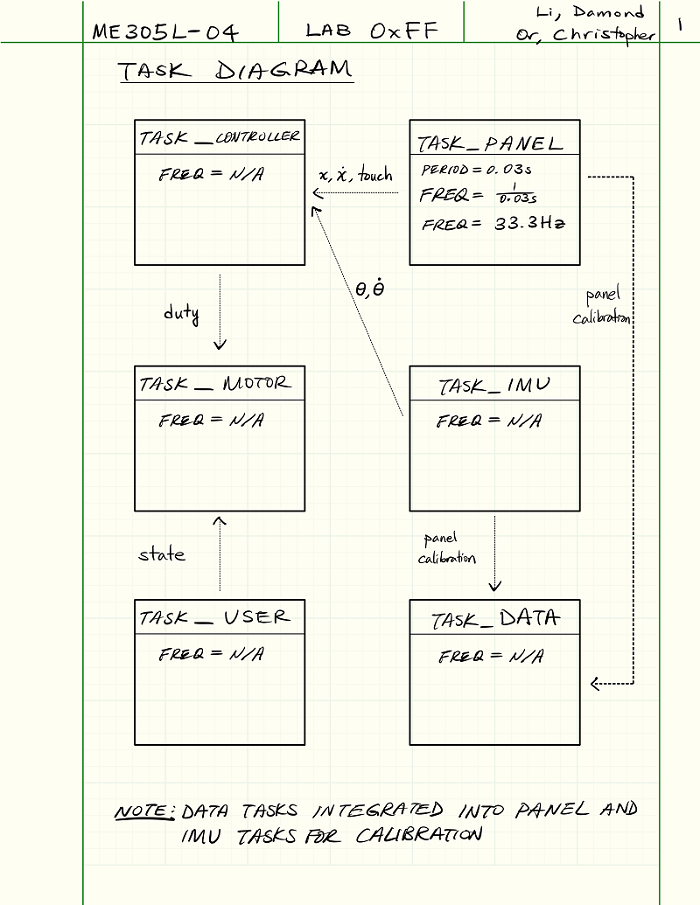

The first step taken for this term project was to create a task diagram describing how

our program operates. Please refer to Figure 1 for the task diagram. From the task

diagram, there were 5 main variables that will be shared across the different tasks:

linear position (X and Y), linear velocity (X and Y), angular position (pitch and roll),

angular velocity (pitch and roll), and duty cycle. The resistive touch panel is

responsible for the linear positions and velocities. The IMU is responsible for the

angular positions and velocities. The controller is responsible for determining the duty

cycle. With that in mind, it would then be a matter of getting each task to output their

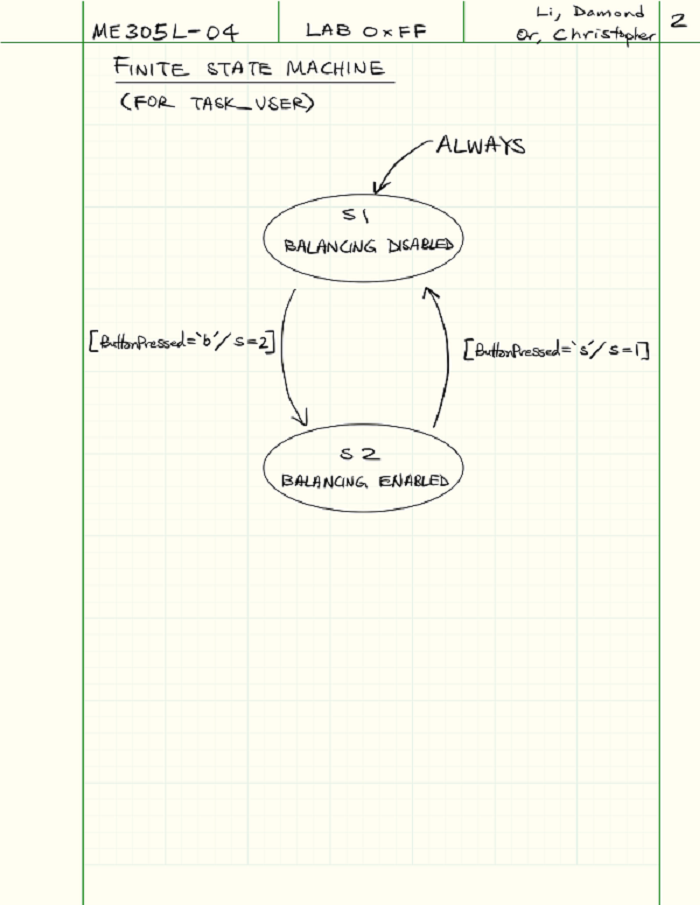

respective data. The finite state machine implemented for our user task is shown in Figure 2.

To model our system, we analyzed the kinematics and kinetics of two systems. The ball

rolling without slip, and the ball and platform as a whole. We then found the equations

of motion of the system that are used in the Simulation section. The hand calculations

used for modeling are shown below:

Below is the MATLAB livescript used to complete the Ball and Platform simulation for HW0x03.

Please click on the following to see the full MATLAB Simulation:

To determine the gains to run our full state feedback controller, a MATLAB script based

off of HW0x03. It was determined that it would be extremely difficult to balance one of

the smaller ball bearings due to its small mass. When the smaller ball bearings roll

across the touch panel as the platform is moving, there are instances where the ball

lifts off from the platform which can be problematic for the controller. A larger ball

bearing with a larger mass is necessary in order to maintain constant contact with the

touch panel. Accordingly, the MATLAB script from HW0x03 was updated with the larger ball

mass and radius to determine the open-loop Jacobian matrix. A closed-loop matrix was

derived by manipulating the open-loop matrices. The poles of the closed-loop matrix was

chosen so that the closed-loop response will have a natural frequency of 8.2, a damping

ratio of 0.8, and two poles at -16 and -17. The gain values were then calculated with the

desired response. Please click HERE for the MATLAB

script used for this calculation.

For the term project, many of the tasks from Lab 0x01, 0x02, 0x03, and 0x04 were updated

to only contain the necessary methods to run our ball and platform system. For example,

task_motor.py previously contained methods to run the motors at a specified speed and

gain value for 10 seconds. That method has been removed from task_motor.py for the term

project. In addition, the hardware for the motor has changed in that the motor is able to

output three times the torque and the motor can no longer fault.

In the middle of debugging the program, it was observed that the program had no problem

balancing the ball in one of the two directions. It was later observed that the source

of the problem is due to the specified coordinate system. In one direction, a positive

rotation causes the ball to accelerate in the positive direction. However, in the

perpendicular direction, a positive rotation causes the ball to accelerate in the

negative direction. The full state feedback controller is designed for the former. In

order to resolve this issue, the positional data was simply multiplied by a negative

before entering the full state feedback controller.